A concrete block retaining Wall or a concrete sleeper? This is a big question! There are so many options when deciding on the most suitable product for your landscaping project. Depending on what your needs are, here’s some key information on concrete block retaining walls and concrete sleepers that will help to determine which product to use.

Concrete Block Retaining Wall

Pros

Concrete block retaining walls are extremely strong, a vital quality when you’re talking about holding up tons of earth and water. After installation, your concrete retaining wall will continue to cure in place, further increasing its strength.Durability

A concrete block retaining wall can stand up to the test of time, often lasting for a century or longer.Resistance

Do you want a retaining wall that’s fireproof, rot-proof, and rustproof? Concrete Block Retaining Walls are perfect for the job. Segmental wall design allows wall to move and maintain structural integrity.Easy to install

Concrete Block Retaining Wall is great for DIY projects. Only requires a shallow (wide footing) – easy for DIY projects. They make it easy to make adjustments or changes to your project at any time. No steel reinforcement or steel posts that require protection to prevent rustVersatile

Concrete block retaining walls will allow you to build curves, angles, or staircases into the retaining wall design with minimum difficulty. You can also create vertical walls, terraced walls, curved walls, various heights and lengths.Attractive Finish

Concrete Block Retaining Walls offer a great range of colour possibilities & design finishes. They can feature a natural stone-look finish perfect for fitting in with the natural environment.Low Maintenance

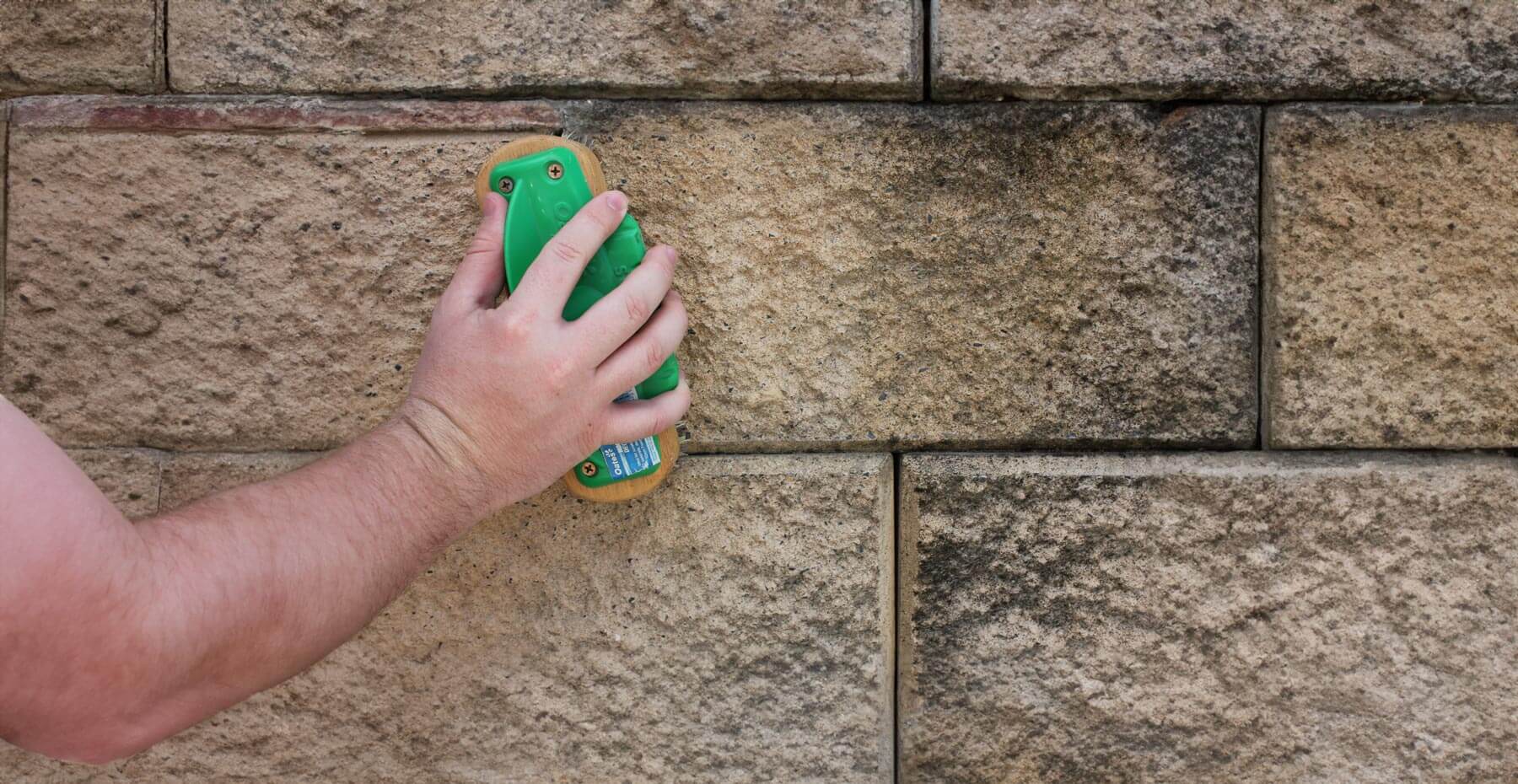

Routine cleaning will keep your Concrete Block Retaining Walls in good condition. This is something that must be done often though.

Concrete Retaining Walls are in the mid-range. If a budget is in mind cost is always a consideration. Although while timber might be cheaper, a concrete block retaining wall system will last longer, so it’s important to take all those considerations into account.

TimeSlightly slower to construct

VS

Concrete Sleepers

Pros

Generally laid on a boundary wall for ease of installation and can be used as an alternative for tight spaces. However, cutting is difficult.Durability

Streamline and strong.

Colours of the sleepers fade quickly. If reinforcement steel starts to rust because of moisture and the sleepers swell and cracks the sleeper loses strength and structural integrity (Steel posts rust if or when the protective coating is damaged or breaks down). Lack of Design Options

Limited colour ranges and finishes and not aesthetically pleasing.Not Versatile

Construction of steps is costly and impractical. Once posts are cemented in the height of the wall is set ÔÇô no putting an additional sleeper on top if extra height is required once wall is constructed.

Limited to straight lines. Construction of steps is costly and impractical.Difficult to Install

Restricted to mainly trade installations which are labour intensive and costly. Not a DIY friendly product as sleepers are difficult to manoeuvre, extremely heavy and can be dangerous to handle. Requires deep holes to be bored into the ground for post holes. Boring deep holes into rocky ground creates challengers and are expensive. If the ground or a post moves (or receives an impact ÔÇô machinery or vehicle) the sleepers dislodge from the channel and collapse.Affordability

Walling costs are increased by steel posts and concrete footings.Stock Issue

Additional sleepers and posts are not stocked by its distributors making supply difficult or expensive on small projects.